Gas Lift is an artificial lift system where gas is injected into a produced well casing to help lift liquids up to the surface throght producing tubing.Continuous gas lift can be adapted to a large range of production conditions in gas wells such as large incline angle wells, high gas-oil-ratio wells.It can enchance oil production,extend gas-well's producing life.

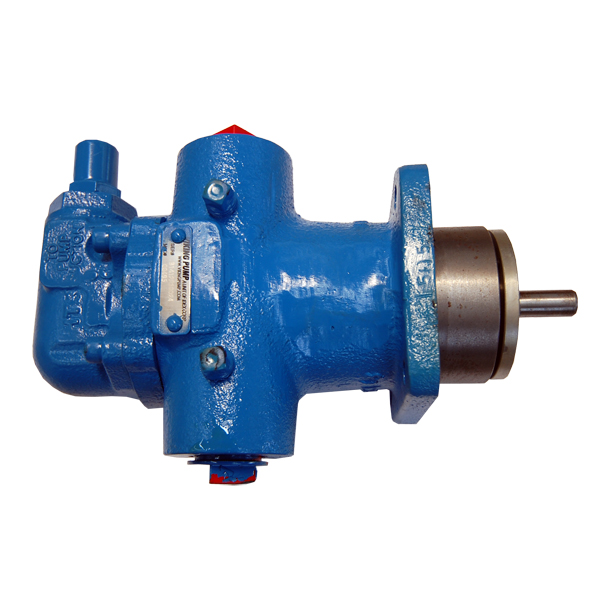

Gas Lift Compressor Package are uesed in oil&gas field for boosting natural gas,nitrogen gas,or air to required high pressure, normally 30-45Mpa,50Mpa and 70Mpa in order to enchance oil output.Gas injecting compressors are usually reciprocating gas compressors with stage range from 3(three) to 6(six).They are driven by electric motor,natural gas engine or diesel engine.Reciprocating compressor packages are built on rigid structural skids.Compressors can be located and relocated as customer's requirements.

Applications We offer specific components, engineered to ensure the performance, safety,and reliability of compressor package. This includes safety options and corrosion resistant materials for those gathering applications where the gas contains acidic or toxic components, such as hydrogen sulfide and carbon dioxide,etc.

How Does It Work? A gas compressor system is provided to operate at a well site and to inject a compressible fluid into a wellbore in support of gas-lift operation. Methods and system are provided that allow for the automated individual control of discharge temperatures from coolers for gas infection,in real time,wherein the temperature control points of the first and/or second stage cooler discharges are automatically controlled by a process controller in order to push heat produced by adiabatic compression to third or final compression stage. In this way,discharge termperatures at the final stage are elevated to maintain injection gaseous mixures in vapor phase.